In the first quarter of 2026, the launch of the "Citron" citric acid production plant is planned in the Voronezh region, as reported by RIA "Voronezh". The project's co-founder, Alexander Lukin, also clarified that "Citron" will be the first plant in Russia to use corn as raw material. The Russian market consumes between 70,000 and 80,000 tons of citric acid annually, mostly imported from China. Lukin explained, "Our competitive advantage lies in having both production and raw materials based in Russia, allowing us to guarantee stable supplies regardless of the geopolitical situation."

Construction of the plant began in May 2023 in the Anninsky district. Currently, the installation of four production workshops, infrastructure, and warehouse facilities is underway. The parameters of the second phase of the project are still being refined and will be adjusted according to economic conditions and the domestic market situation. Initially, "Citron" was planned to be launched in 2024, but the timeline was pushed to 2025. However, production volumes have been increased from 10,000 tons to 20,000 tons of citric acid per year, with investments rising from 3 billion rubles to 10 billion rubles.

In the past, citric acid production in Russia was handled by the company "Citrobel" in the Belgorod region; however, in 2017, production was halted due to a court decision concerning environmental damage. Later, the newspaper "Kommersant" reported that the company had no plans to resume operations.

Oleg Radin, the President of "Soyuzkrahmala," notes that currently, only a few biotechnological projects are announced in Russia. This is primarily due to technical complexity and high levels of risks. Moreover, the number of successful enterprises that have gone through all stages of development and become profitable is limited. Therefore, the successful implementation of the "Citron" project will depend on several factors: selecting the right technological partner (currently, a Chinese company is the most likely), equipment efficiency, and the use of microorganism strains. The quality of the final product is also crucial, as it determines the project's payback period.

Among the competitive advantages, Radin points out that currently, citric acid is imported from China. He believes, "It is known that its prices have significantly decreased over the past two to three years. However, considering trends in industrial biotechnology, the cost of citric acid will likely rise again, although it will take time. Therefore, for an enterprise successfully entering production, it is important to 'get back on its feet'." He also mentions similar projects being implemented in the Tula region with a similar product range. "The company that is the first to enter the market may receive advantages from the state in the form of support and import quotas," Radin concluded.

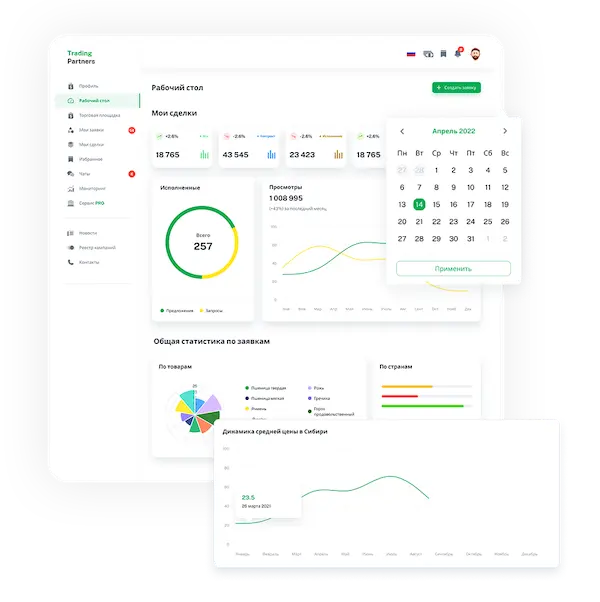

Trading platform

Trading platform

Monitoring

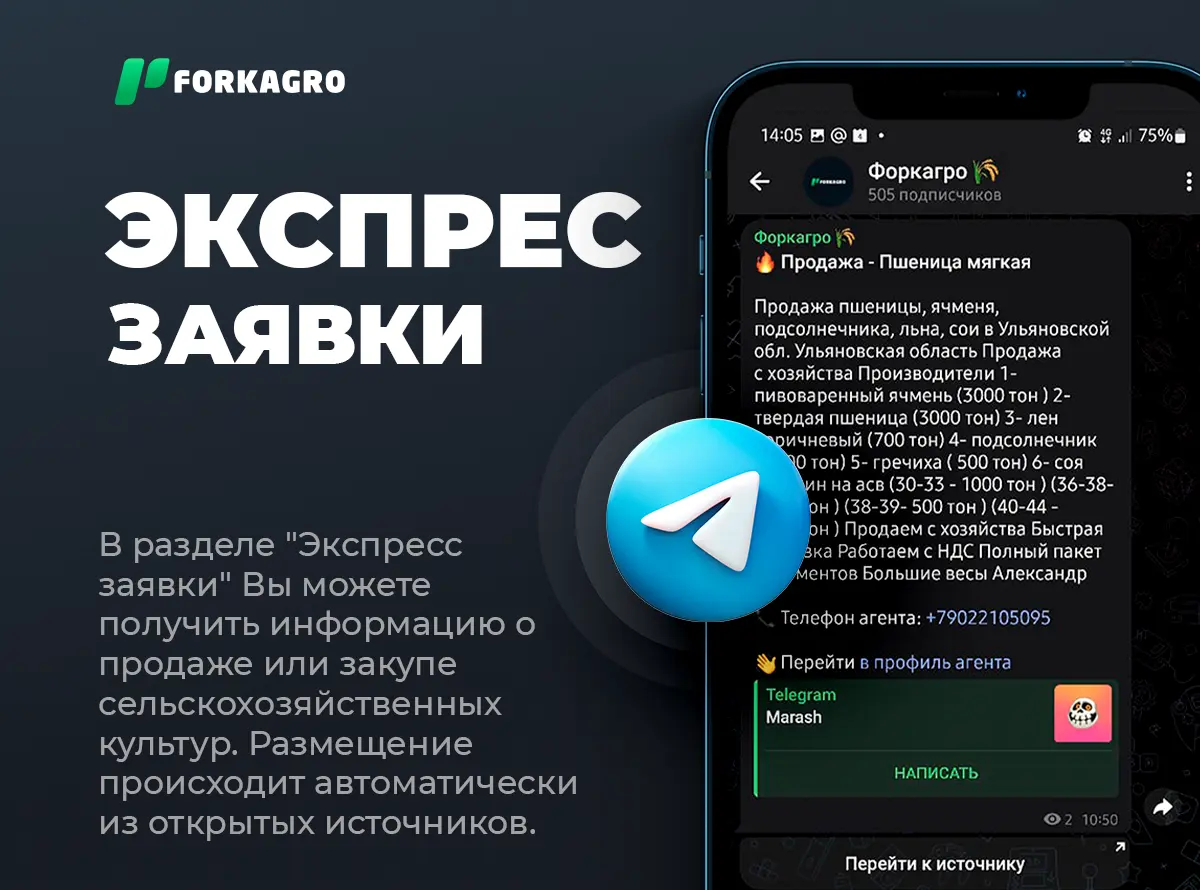

Monitoring  Express applications

Express applications

Fork Work

Fork Work

Service

Service  News

News  Directory

Directory