The first owners of shredders were four agricultural producers who are exemplary farms in the region, as well as loyal users of equipment from the Altai Machine-Building Plants. It should be noted that the total number of Almaz Shredders owned and used by farmers in their work exceeds 35 units.

The KIP-14 shredder has a working width of 14 meters and is compatible with tractors with a power of 250 hp. The tool is suitable for shredding plant residues of sunflower, corn, rapeseed, as well as working with cover crops.

After passing the roller-shredder on the soil, plant residues remain, which protect the soil surface from overheating, regulate temperature, preserve moisture, prevent weed growth, and protect against wind erosion. In addition, the unit helps to destroy the habitat of pests and insects in soils where corn, sunflower, and rapeseed are grown.

The tool provides high productivity in shredding plant residues: the KIP-14 can process up to 16.8 hectares in one hour of work at speeds up to 20 km/h. Low traction resistance allows for reducing fuel consumption.

The shredder consists of 5 sections. Thanks to the tandem arrangement of the drums, the unit operates continuously. Effective shredding of crop residues is achieved due to the cross arrangement of knives on the drums. The knives are made of 6 mm thick 30MnB5 steel and are fastened with 4 bolts. The tool processes the soil to a depth of 3 cm.

Uniform distribution of pressure on the working elements across the entire width of coverage is ensured by the frame construction, which results in uniform processing across the entire width of the unit. Adjustment of roller pressure on the soil is done mechanically with the help of 4 turnbuckles.

Switching from transport position to working and back is done hydraulically by one operator who remains at his workstation. All hydraulic hoses are protected from mechanical damage.

Folding the wings allows for transporting the unit on public roads (transport width 2.88 meters). The KIP design also allows for working in reverse.

The in-house production of components allows for quickly replacing spare parts, which is necessary to prevent downtimes in work and reduce downtime for farmers.

After the delivery of the KIP-14 to the farmers, service specialists from the Almaz plants will assemble the units and prepare them for the start of spring field work. Soon the KIP-14 will start its first working season.

We thank the farmers for their trust and acquisition of new Almaz equipment! We hope for further successful cooperation and wish you high-quality and record-breaking harvests in the new season!

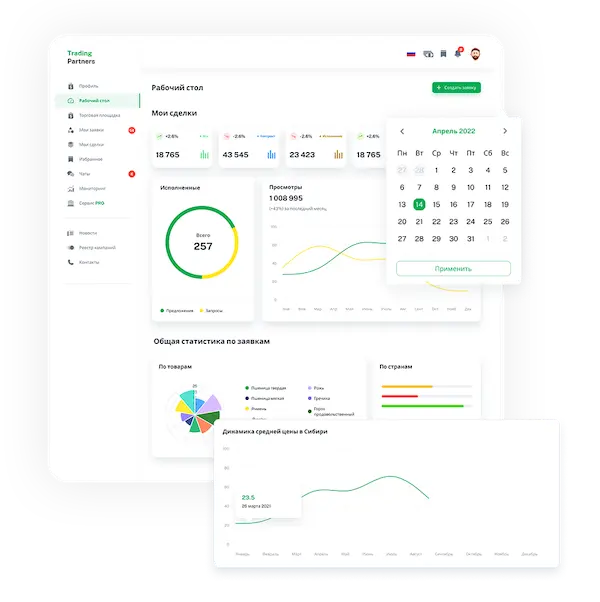

Trading platform

Trading platform

Monitoring

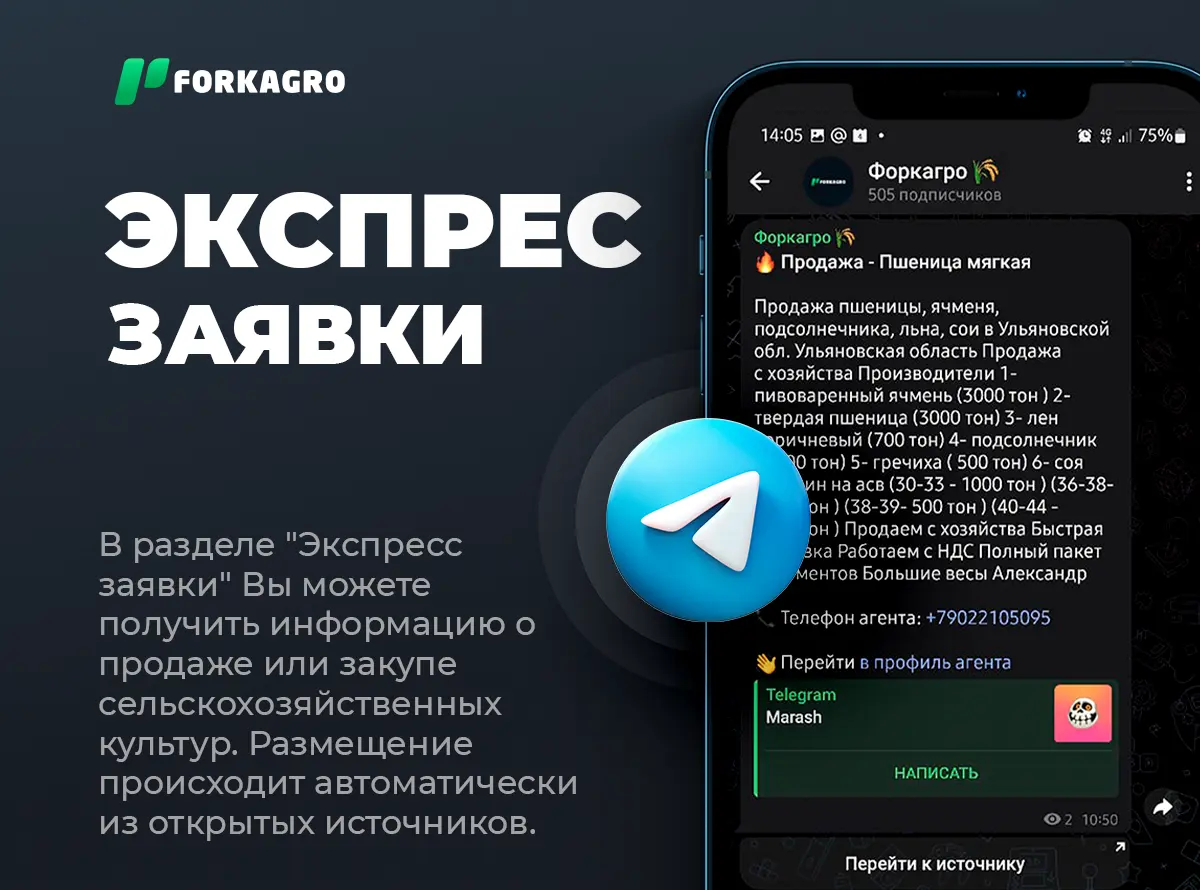

Monitoring  Express applications

Express applications

Fork Work

Fork Work

Service

Service  News

News  Directory

Directory