In Russia, the process of localizing the production of all common types and formats of packaging for food products has been implemented, as reported in the materials of the National Union of Milk Producers ("Soyuzmoloko").

Based on the results of the conducted research, the organization indicates that by 2024, all mass types of packaging for dairy products, including packaging for baby food, had been fully localized.

One of the main factors contributing to stability is the domestic production of aseptic packaging, which is widely used for baby food and ensuring the remote regions of the country. Currently, this type of packaging is produced at one of the largest European factories owned by the company "Packaging Systems," with a capacity of up to 5 billion packages per year.

Manufacturers continue to actively work on complex types of packaging. The majority of Russian producers have significantly increased production volumes and are implementing new investment projects in the field of packaging (companies like "Packaging Systems," Danaflex, "Lambumiz," "Molopak," among others).

According to the National Union's data, 12.8 million tons of products are packaged annually in the Russian dairy industry, requiring 32.2 million packages of various types and compositions. Specifically, multilayer cardboard accounts for 31% of the total packaging volume, PET bottles - 17%, flexible polymer packaging - 25%. Other materials, such as high-density low-pressure polyethylene (HDPE), paper, plastic, and foil, make up the remaining volume.

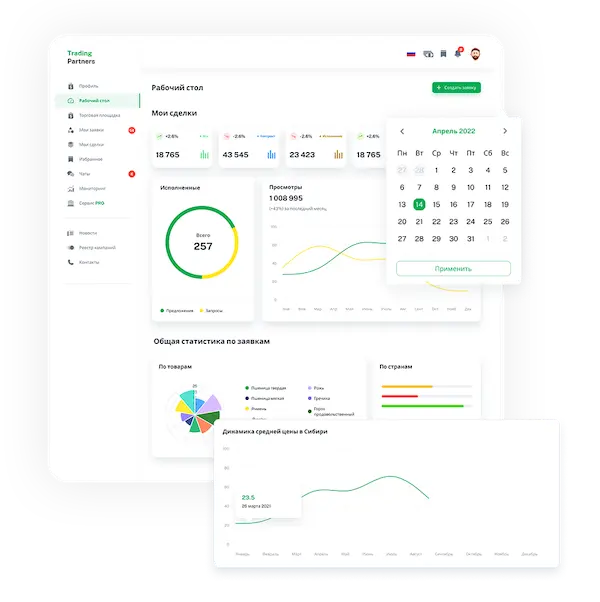

Trading platform

Trading platform

Monitoring

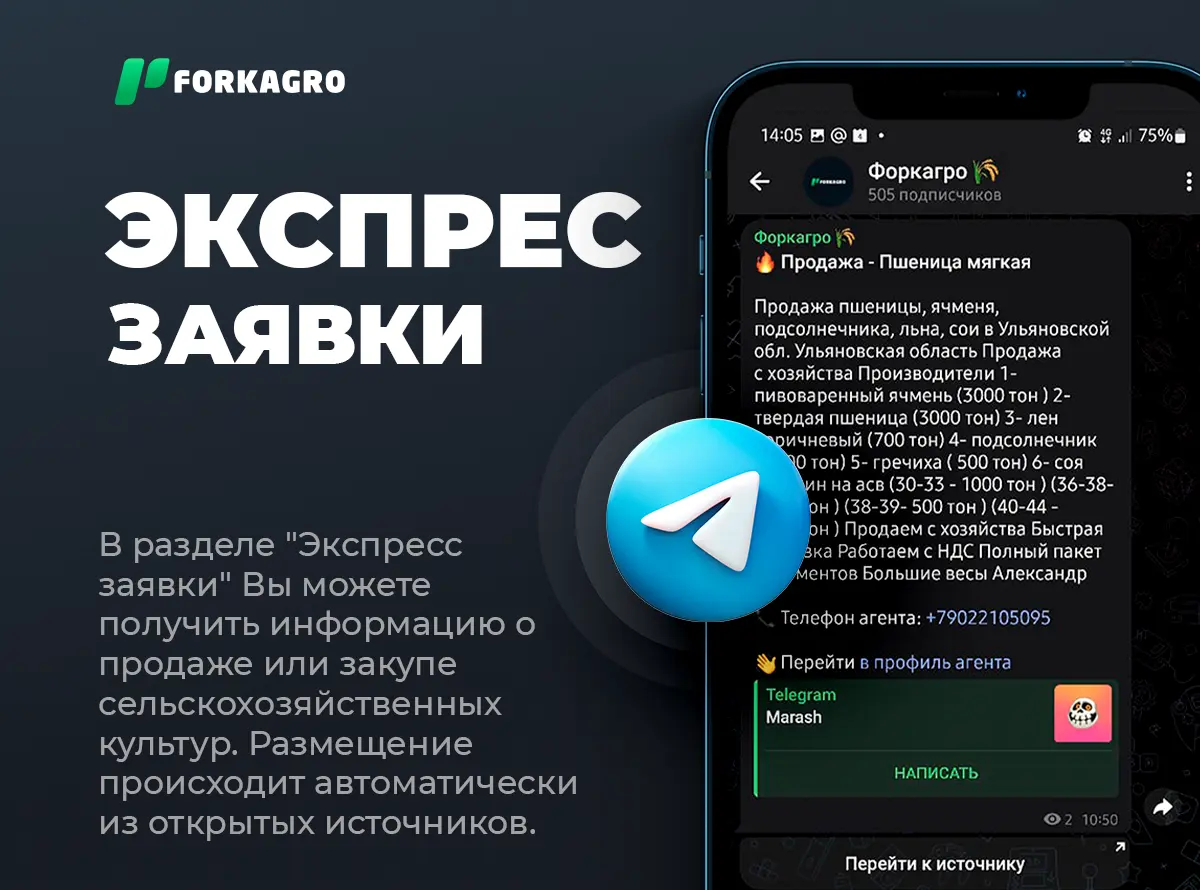

Monitoring  Express applications

Express applications

Fork Work

Fork Work

Service

Service  News

News  Directory

Directory