"Agrо-Belogorye" will expand agricultural machinery production.

ZMS-Technologies plant, opened in 2017 in Agro-Belogorye, is developing the production of trailed soil cultivation machinery. It has shifted from import substitution to producing equipment for the energy sector, including ring-gear rollers, disc harrows, and shredders. The company plans to release 8 new units of machinery by 2025. The company aims for import quality at a more affordable price, actively collaborating with Russian manufacturers.

The plant "ZMS-Technologies", opened in 2017 by Agro-Belogorye Group of Companies in partnership with German companies, will develop the production of trailed soil cultivation equipment. "Currently, industrializing the country is a top priority, so the development of ZMS-Technologies is one of the main tasks," said Vladimir Zotov, Chairman of the Board of Directors of Agro-Belogorye Group of Companies, to Agroinvestor. "We established the enterprise with two German companies. We are now completing the process of buying out the shares of foreign partners. And this is our initiative: our German colleagues were ready to continue cooperation, but we decided to become fully independent. The plant is not part of the Agro-Belogorye Group of Companies but represents a division of prospective development supervised by our holding. The plant is equipped with unique equipment, has already formed a good team, and, I think, has everything to secure a strong position in the market."

Initially, the plant was created with the aim of import substitution of foreign equipment for livestock complexes. Currently, in addition to livestock equipment, the enterprise is involved in the production of components for the energy sector, provides powder coating services, and the key direction becomes the production of trailed soil cultivation equipment.

Currently, the plant produces ring-toothed rollers "Belogor" of various modifications, disc universal harrows "Lyubava", suitable for both classic and minimum soil processing, and crop residue shredders "Ratibor". The working width of the rollers is 8.2 m, 10.4 m, and 12 m, and work is underway on a 15 m wide unit, shared commercial director of ZMS-Technologies Natalya Merzlikina. "We participate in major exhibitions, held demo shows in Kazakhstan - where the tillage is not yet developed, but nevertheless three of our units have been sold to local farms and, according to feedback, performed well. For the "Agros" exhibition, we are preparing the "Belogora" model, which will be equipped with a perennial grass seeding system," she told Agroinvestor.

Also, the plant's design bureau is developing a universal cultivator with a working width of 9 m and 12 m, a deep ripper, and a toothed flexible harrow. By the end of 2025, the plant plans to produce a range of eight units of soil cultivation equipment. "We strive to make the machines fully hydraulic so that one mechanic can fold and unfold any unit, as there is currently a critical shortage of specialists," says Merzlikina. "At the same time, we have moved away from using construction steels and use structural steels, which makes the equipment more expensive but also allows us to create a good strength reserve in the frame, which is crucial. Our units are heavier than those of the main competitors, providing greater soil pressure and better seed-to-soil contact." According to Merzlikina, ZMS-Technologies equipment is positioned in the mid-price segment: if imported counterparts cost 5-6 million rubles, then products of Belgorod production - about 3 million rubles.

"We are not reinventing the wheel, but we strive to make equipment of quality comparable to that of imports, but at a more attractive price," notes the plant's general director Yevgeny Denisenko. "We cooperate with metallurgical plants, consider new grades of steel that were previously exported but are now available on the domestic market due to sanctions. Manufacturers are in good contact with our designers, talking about different properties of steel. We establish cooperation with plants that used to work in the European market: now they produce castings for us. For example, this is how we set up the production of bearing housings assembled."

There are no plans to start the production of self-propelled machinery at ZMS-Technologies yet; the plant intends to remain in the segment of trailed implements but will enhance their functionality. In addition, the direction of equipment production for pig farming continues to develop, with a focus on increasing technological sophistication. "You can make a trough or feeder in any garage, it's a low-margin business," says Denisenko. "Since some foreign manufacturers have left the Russian market, we need to replace them. For example, we have already mastered the production of all components of feeding systems - both drive and chains."

Interest in the soil cultivation equipment of ZMS-Technologies is shown by both large agroholdings and small farms, notes Yevgeny Denisenko. The plant is currently being reprofiled, with further expansion of the machine park planned. Additional machines for the production of pig farming equipment and its components will be added. "For example, chains for feeding lines, as it turned out, are practically not produced in Russia, although this is not an innovation at all. We have mastered the production of one standard size of chains, now we are expanding the range, actively sending our chains for test trials to the leaders of the Russian agro-industrial market and small enterprises," he adds.

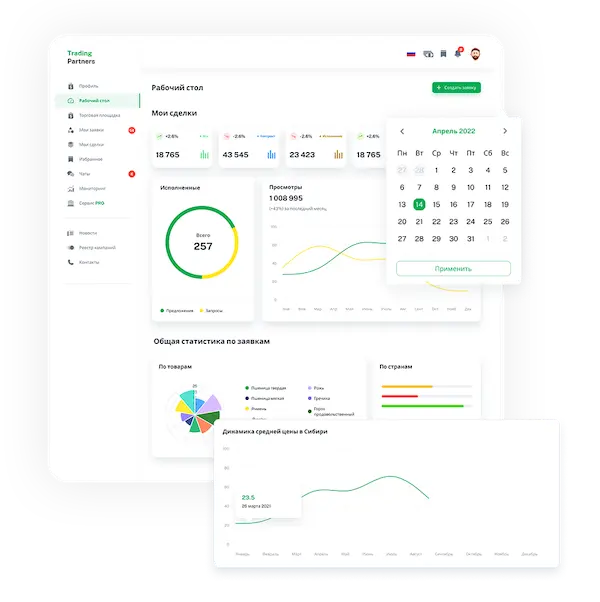

Trading platform

Trading platform

Monitoring

Monitoring  Catalog

Catalog

Fork Work

Fork Work

Service

Service  News

News  Directory

Directory