Dried milk is a popular and in-demand product on the international dairy market.

To preserve milk and conserve it, the drying process involves heat treatment to reduce the number of bacteria, as well as concentration by evaporating to about 45-52% solid matter before spraying into a stream of hot air. Within a short period of time (5-30 seconds), milk droplets turn into powder and are separated from the air stream using cyclones or sleeve filters. An important feature of the spray drying method is that the moisture content in the powder is reduced to a level where bacteria multiplication does not occur, and the functional properties of the milk components are preserved almost unchanged.

On August 27, 2024, under the control of the Northwest Interregional Administration of the Rosselkhoznadzor, a batch of 25 tons of dried milk was sent to Algeria. This milk was produced at one of the dairy processing plants in the Vologda region. State inspectors of the Rosselkhoznadzor Administration conducted an inspection of this batch for compliance with the veterinary requirements of Algeria, the importing country.

Algeria became the third country, after Azerbaijan and Uzbekistan, to start receiving dried milk from the Vologda region. Since the beginning of 2024, 266 tons of this product have been exported to the Algerian region.

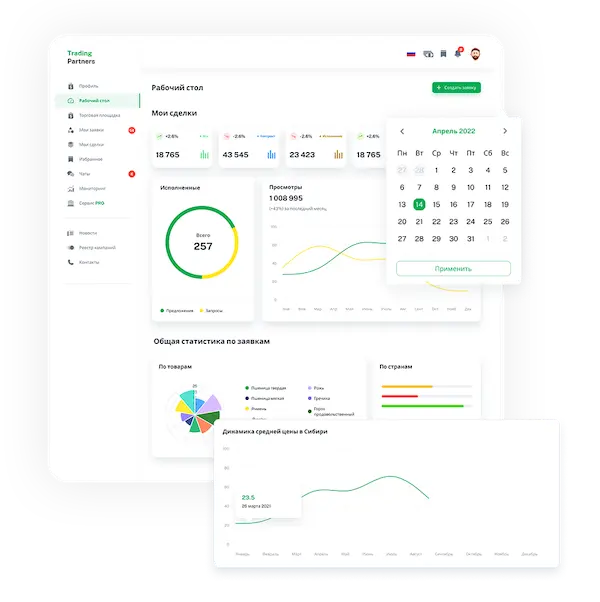

Trading platform

Trading platform

Monitoring

Monitoring  Catalog

Catalog

Fork Work

Fork Work

Service

Service  News

News  Directory

Directory